Insulation kit

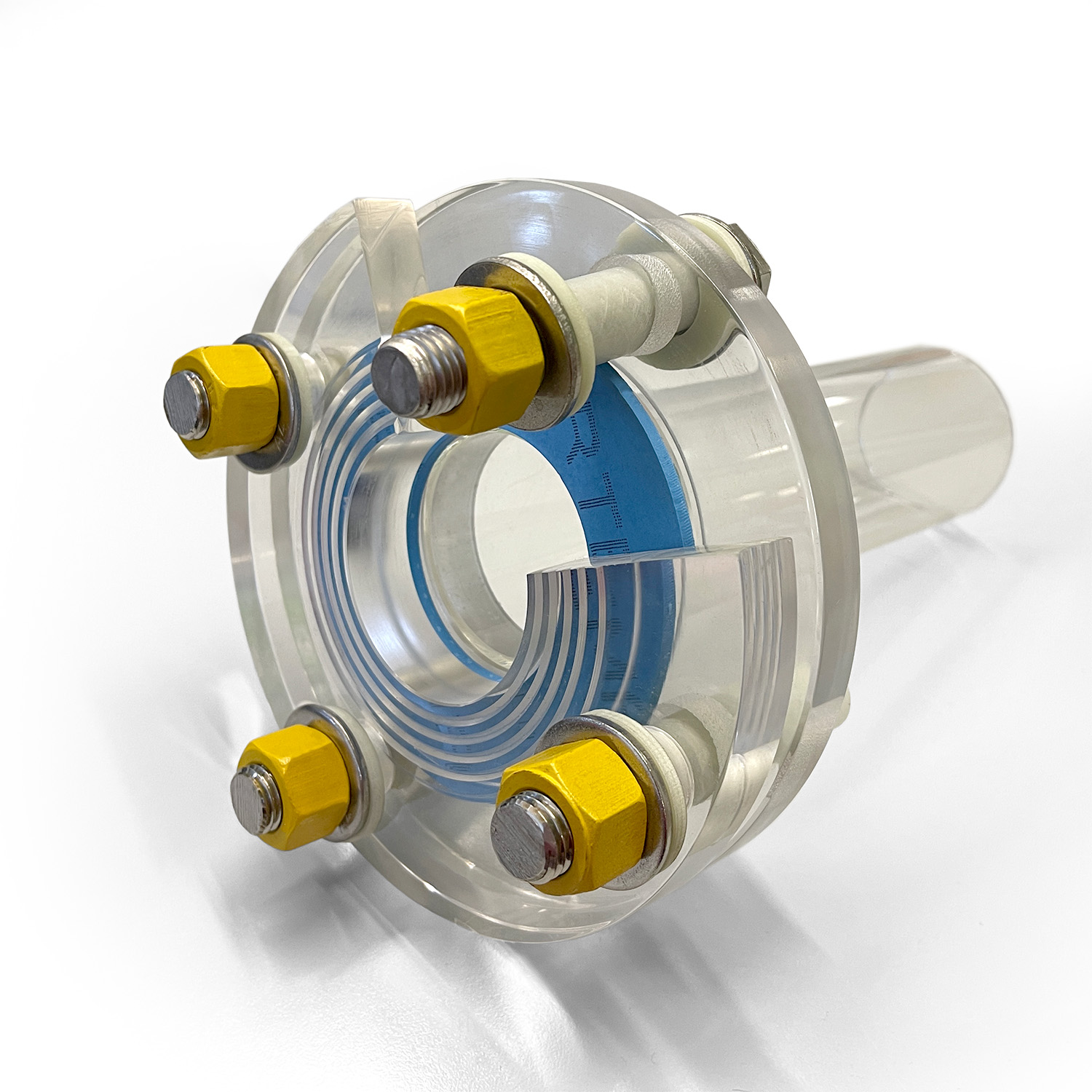

Insulation kit FIk 1 with UNIVERSAL 400

|

Temperature max |

+350 °C |

|

Temperature min |

-40 °C |

|

|

Pressure max operating |

100 bar |

The FIK 1 INSULATION KIT is widely used for the electrical insulation of flanged couplings at non-heavy conditions (low temperatures, low pressures, non-corrosive/toxic media) where, however, electric...

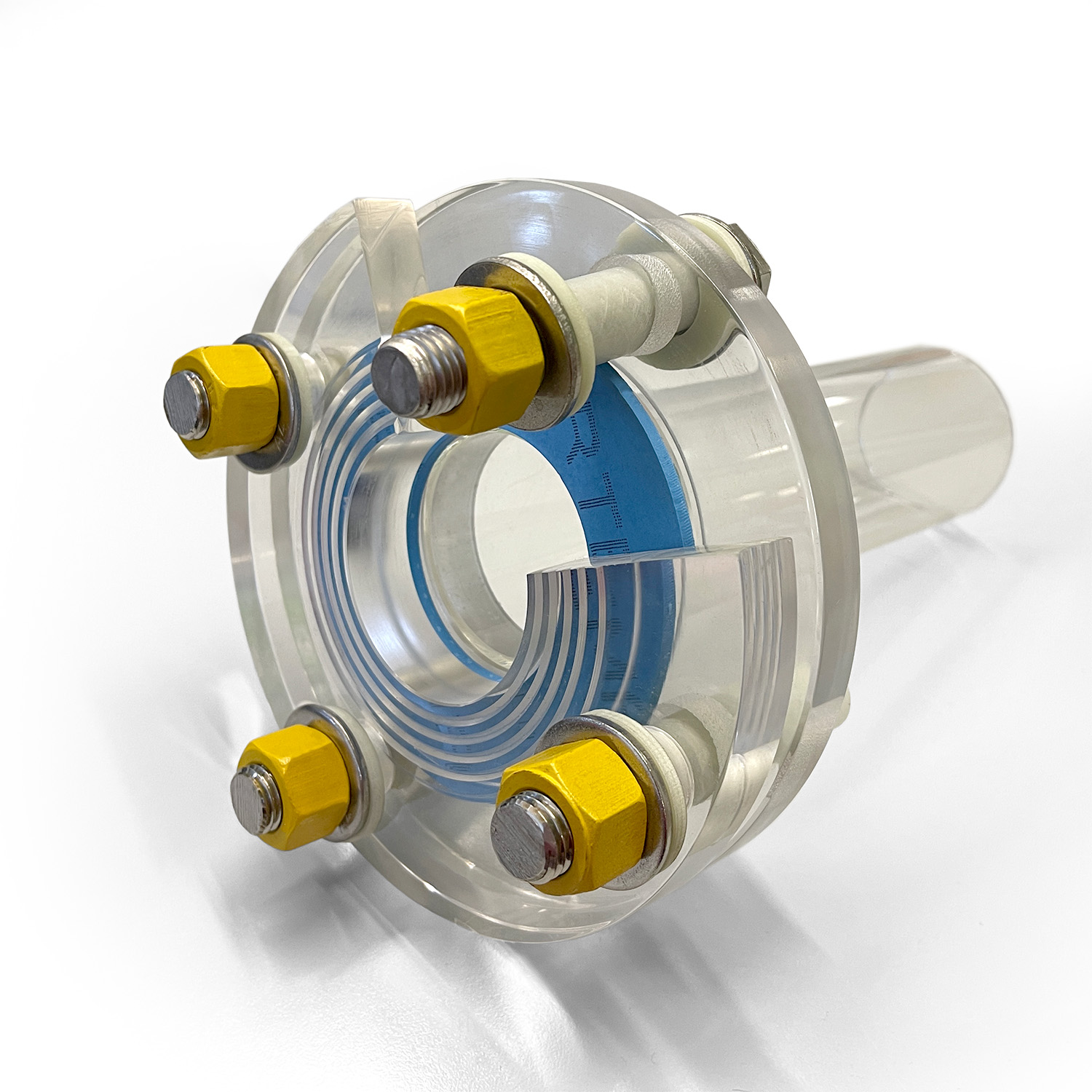

Insulation kit FIk 2 with BLUON 7030/G

|

Temperature max |

+260 °C |

|

Temperature min |

-200 °C |

|

|

Pressure max operating |

85 bar |

The FIK 2 INSULATION KIT is widely used for the electrical insulation of flanged couplings on applications in the presence of corrosive fluids (acids and bases, pH 0÷14).

The FIK 2 INSULATION ...

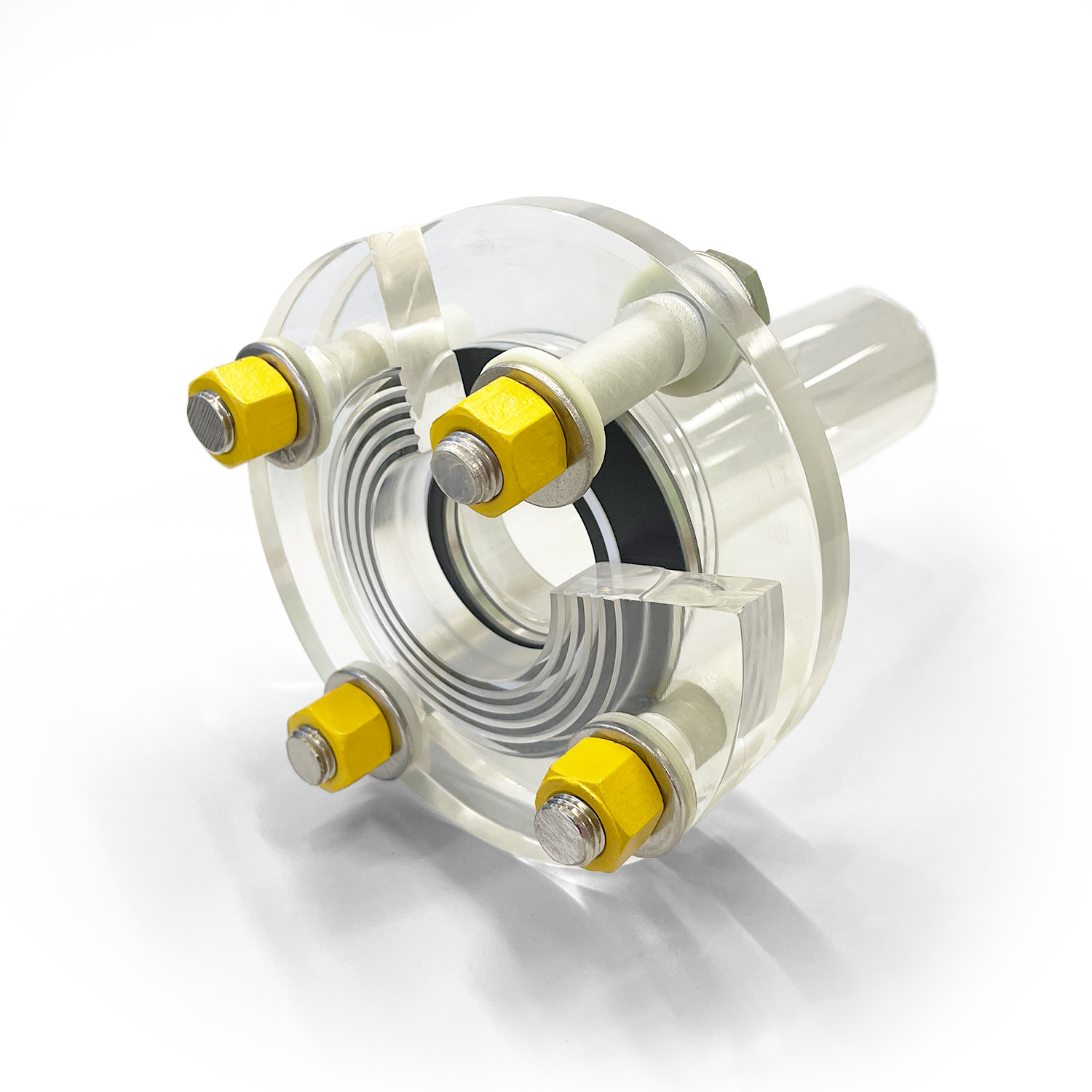

Insulation kit FIk 3 with VCS

|

Temperature max |

+180 °C |

|

Temperature min |

-20 °C |

|

|

Pressure max operating |

700 bar |

The FIK 3 INSULATION KIT is widely used for the electrical insulation of flanged couplings in the presence of high pressures (over 100 bar) and dangerous fluids, where traditional insulating gaskets...

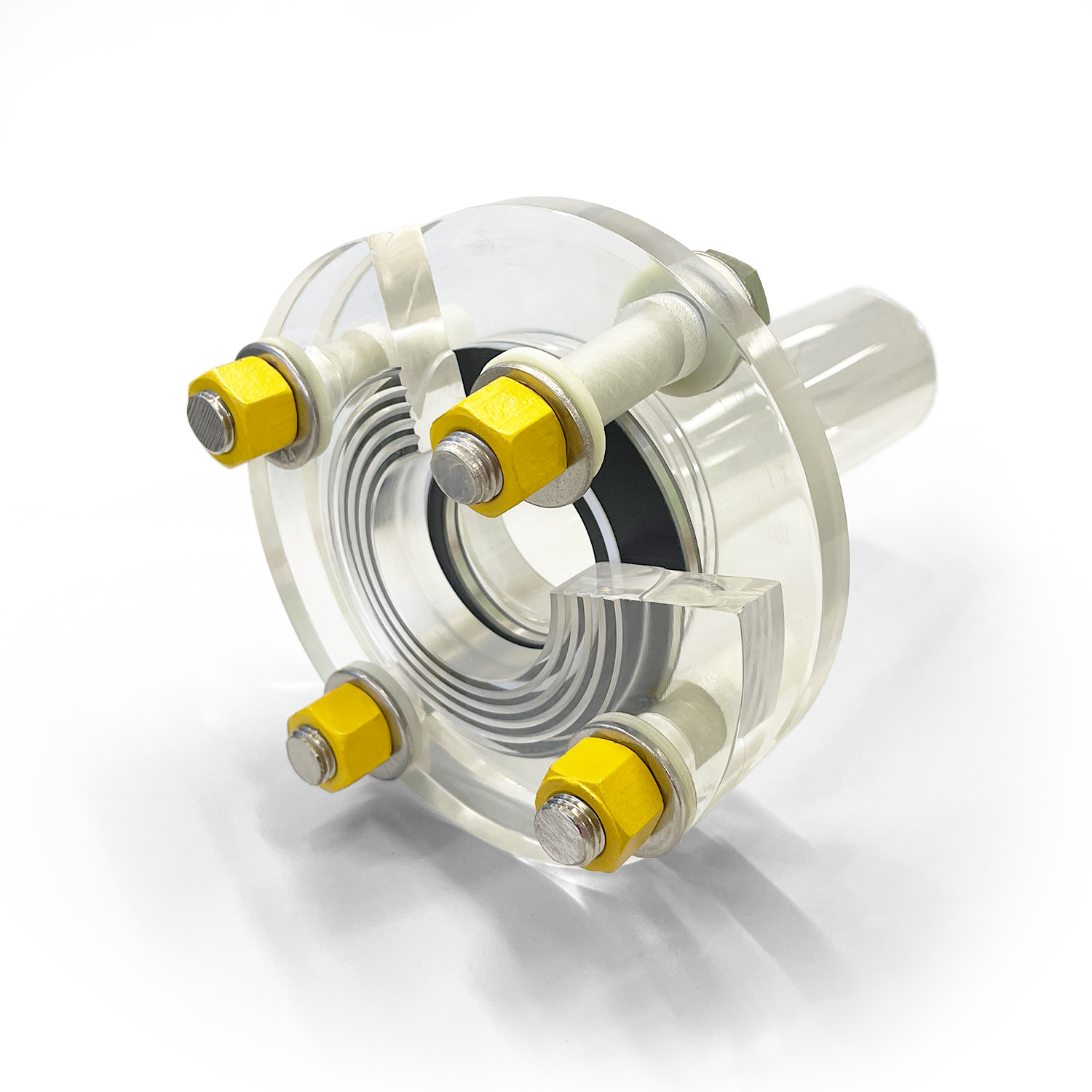

The INSULATION KIT represents an important technological innovation in protection of flanged couplings from galvanic currents. The galvanic corrosion phenomenon rises when two materials with different electrical potentials (e.g. stainless steel - carbon steel) are in direct contact with each other. In this way, a short-circuit stack (galvanic cell) is forming and the electrodes are making up of the two coupled materials. So, a flow of electrons generates from the higher potential material (anode, it oxidizes), towards the lower potential material (cathode, it decreases). The result of this phenomenon is the galvanic corrosion of the materials. The INSULATION KIT installed on the flanged coupling prevents this phenomenon. This solution electrically isolates the flanges and its components (tie rods and nuts) and prevents electrical charges passing between the flanges along the piping line.