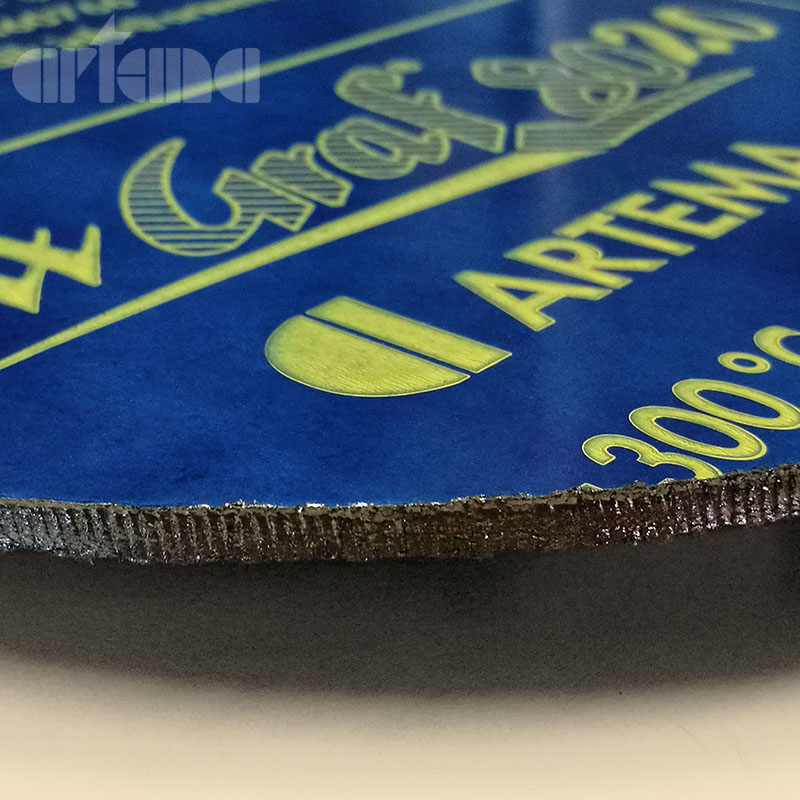

Die-cut aramid gaskets: NEWGRAF 8020/II Gen.®

Properties

The NEWGRAF 8020®/II Gen. is made with 80% graphite fiber (chemical resistance

and temperature), 15% Kevlar® (mechanical strength) and 5% between NBR elastomeric binder

components and special additives.

The combination of graphite and ...

- 80% COMPRESSED GRAPHITE

- EXCELLENT CHEMICAL RESISTANCE

- HIGH COMPRESSION RESISTANCE

- COVERS 80% OF INDUSTRIAL APPLICATIONS

- GREAT ADAPTABILITY

- ANTISTICK TREATMENT ON BOTH FACES

- NUMEROUS CERTIFICATES

Technical data

| Temperature max: | +300 °C |

| Temperature max with steam: | +200 °C |

| pH: | **** |

| Temperature max operating: | T. +260 °C |

| Pressure max operating: | P. 100 bar |

| Color: | **** |

| Marking: | **** |

| Density: | **** |

| Chlorides: | **** |

| Compressibility ASTM F36 J: | **** |

| Recovery ASTM F36J: | **** |

| Compressive strength: | **** |

| Ignition loss at 800 °C DIN 52911: | **** |

| Stress resistance 50 Mpa 6h/300 °C DIN 52913: | **** |

| Tensile strength longitudinal/transversal DIN 52910: | **** |

| Specific leak rate (gas) DIN 3535/6: | **** |

| Dielectric resistance (IEC 243 - 23 °C): | **** |

| Weight increase (ASTM F 146): | |

| - oil IRM 903 (5 h/150 °C): | **** |

| - fuel (5 h/23 °C): | **** |

| Thickness increase (ASTM F 146): | |

| - oil IRM 903 (5 h/150 °C): | **** |

| - fuel (5 h/23 °C): | **** |

| Anti-stick treatment: | **** |